Home > Processing Equipment > Extraction Systems > Polaramax Hero

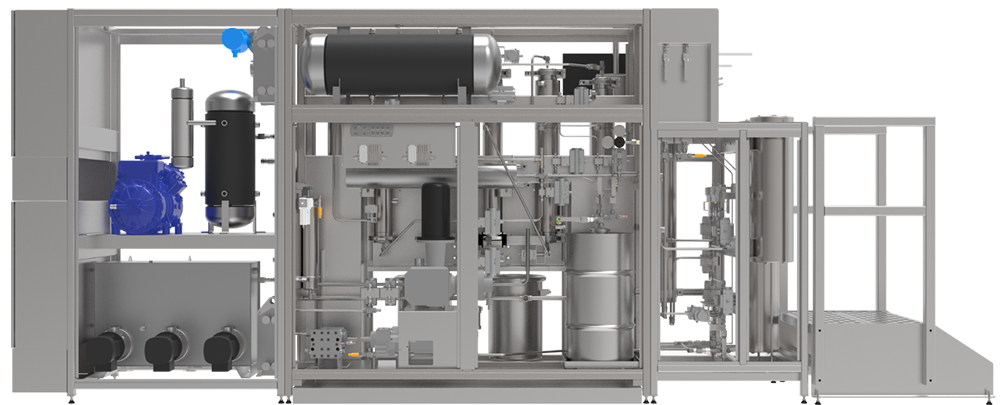

Polaramax™ Hero

Our flagship solution for clean, efficient, flexible extraction operations.

Integrated multi-solvent extraction technology allows you to use CO2 alone or CO2 plus a small amount of cosolvent.

NEW! Add a Vitalis Airo™ D-4 system for rapid, continuous, hands-free winterization.

Get automated in-line dewaxing, decoloring, desolvation, and decarboxylation in one system with touchscreen operation.

CO2 & Multi-Solvent Extraction Systems

Hero 20 | Hero 40 | Hero 45 | Hero 65 | Hero 90

-

Extraction

Vessel volume: 20 L / 45 L combinations

Total extraction vessel volume: Up to 90 L*

Liquid CO2 pump: Up to 10 kg/minute

Integrated multi-solvent system

Temperature range: 10–150°F (-12–65°C)

Pressure range (standard configuration):

MAWP: 2,200 psi (151 bar)

Operating pressure: 500–2,000 psi (35–137 bar)

Pressure range (high-pressure upgrade):

MAWP: 5,000 psi (345 bar)

Operating pressure: 500–4,800 psi (35–331 bar)

-

Separation & Collection

Continuous CO2 purification

Pressure range: 300–720 psi (21–50 bar)

Temperature range: 40–100°F (4.4–38°C)

Dedicated terpene collection

Separate collection lines for each extraction vessel*

-

CO2 Recovery & Storage

Closed-loop CO2

CO2 condenser

CO2 remediation filters

-

Control Panel

Multiple user levels

Real-time monitoring

Remote diagnostics / remote connectivity**

Live batch recording

-

Continuous Operation

Continuous cyclone separation*

Dual extractor configurations

-

Specifications

Weight: 5,400–6,140 lbs (2,450-2,785 kg)*

Footprint (LxWxH): 230” x 48” x 95”

(5.8m x 1.2m x 2.4m)

-

Certifications, Compliance & Warranty

ASME/NB

CSA-CRN

PED-CE

CUL/UL

AS/NZS 1200

EU-GMP*

UKCA

Lifetime warranty*** on all pressure vessels

One-year warranty on all other components

Service plans available

-

Site Requirements

Pneumatic supply ISO 8573-1 [5:4:3] @120 psi 12 SCFM

Broadband internet connection

Power requirements (North America):

460V 3Φ 60Hz

Power requirements (EU, AUS, NZ):

400V 3Φ 50Hz

Avg. operating power: 58 kWh / Max power: 77 kWh

-

Additional Standard Features

Automated process controls

304 stainless-steel contact surfaces

Flow meter

Ethanol wash sequence / CIP compatibility

Integrated CO2 (R744) refrigeration

HMI designed to ISA 101.01

Automated programmable start-up & shutdown

2 x 20 L pre-loadable biomass cartridges

Pre-loaded recipes

User-programmable recipes

Over-the-air software updates**

Remote diagnostics capability**

Managed project implementation

Professional commissioning

On-site operator training

-

Optional Features

316 stainless-steel contact surfaces

CIP (clean-in-place) system****

In-line extract filtration

Extended service plan

Additional biomass cartridges

Bulk CO2 storage solutions

Vessel expansion

Higher pressure configurations

Managed door-to-door logistics

-

Optional GMP Support Assets

We can provide the following GMP documents:

URS

FRS

Requirement traceability matrix

PHA

FAT

SAT

IQ

OQ

Calibration certificates

Technical design documents

Wetted materials traceability

Software disaster recovery plan

Vitalis Extraction Technology’s management system—for the design, manufacturing (welding and assembly), installation, and service of extraction technologies and commercial refrigeration—is certified as being in conformity with ISO 9001:2015 by Intertek.

Find out if the Polaramax™ Hero is right for you.

Let’s talk about your goals and create a plan that makes sense for your budget.

* Depending on configuration.

** Requires broadband internet connection.

*** Defined as 100,000 cycles.