Versatile CO2 Know-How for Mission-Critical Applications

R744 heat pumps for commercial, industrial, and district-energy applications

CO2 recovery solutions

CO2 and multi-solvent extraction and refinement systems

Sustainability through better performance, not sacrifice.

People. Planet. Profits. The triple bottom line. It's what clean technologies utilizing CO2 can help deliver. For a future of thriving.

Vitalis helps companies and communities transition to that future, today.

Ready to make it happen?

-

Extraction Systems

Get more from the heart of your processing operation with an efficient, flexible, compliant system that can grow with your business.

-

Refinement Systems

Say hello to a single automated in-line system for winterizing your extract in a way that’s fast, space-saving, and cost-effective.

-

R744 Heating & Cooling Systems

Lower your carbon footprint and energy costs with systems that use a natural refrigerant for higher efficiency, performance, and sustainability.

-

CO2 Recovery Systems

Reclaim and purify CO2 from a process such as fermentation to minimize spending on supplied CO2 and reduce your environmental impact.

Companies Love Working With Vitalis

From growing startups to established industry leaders, many organizations are achieving sustainable success with our help.

Cleantech Solutions for Evolving Industries

-

Food / Beverage / CPG

Produce clean, value-added ingredients for premium consumer packaged goods.

-

Pharma / Nutraceuticals

Formulate pure, consistent products of the highest quality—compliantly and at scale.

-

Industrial Sustainability

Tap into CO2 innovations that make industrial processes environmentally friendly.

What People Are Saying

-

“We’ve worked with a lot of CO2 technology vendors throughout our time in the medical cannabis industry. The professionalism, customer support, and dedication—on top of their technology—has made partnering with Vitalis a clear choice.”

—Jessie Kater, Senior VP of Innovation and R&D at Curaleaf

-

“Vitalis has been the star of our show in manufacturing. The extraction the machines provide has been ahead of the curve since 2019. We have had high-capacity, top-of-the-line extraction, and Vitalis is constantly making improvements, which puts them ahead of their competition. I do a lot of consulting work, and I’m exposed to a large variety of machines. Every time I find a machine that does something new and exciting, I discover that Vitalis was able to do that thing the whole time and they do it more efficiently. The only thing that’s been more enjoyable than these machines is the customer service. In our industry, we don’t get a lot of positive customer service, so excellent service really stands out and is greatly appreciated.”

—Leah Kincaid, CEO, Dynamic Processors

-

“Working with Vitalis for 7 years has made 3 things crystal clear: 1) Their systems are built for producing oils of the highest quality, which is paramount and exactly what we've achieved; 2) We have exceptional control over the extraction process, perfect for fine-tuning our formulations; and 3) The Vitalis service team are absolute rock stars, major players in our success.

“By the time Redecan was sold for $CA925 million, we had a fleet of Vitalis Q-90 and R-200 systems. Now, some of us from that original team are taking what we learned and expanding to new geographies, not just in Canada, but the U.S. as well. With new Vitalis extraction systems and cool innovations like the CIS and Airo system, the team is geared up to produce some amazing oil for those markets, at a faster pace and lower cost of production than ever.”

—Jackie Fletcher, former Vice President of Extraction Science & Innovation, Tilray Brands

-

“Transforming the landscape of cannabis extraction, Christina Lake Cannabis stands at the forefront of innovation and quality in Canada. In the competitive world of cannabis extraction, our partnership with Vitalis has been a game-changer. Originally using the R-200 extraction system, we were running mono-solvent CO2, impressed with the machine's reliability and output. But since adding the Cosolvent Injection System (CIS) and other novel upgrades, we've seen massive improvements in our throughput and crude oil quality.

“Where we used to extract about 90 kg of biomass per day, we're now pulling around 360 kg—a substantial increase of 300%. We can now process at least 100,000 kg of biomass each year, something that's critical to our scale-up plans. What used to be a labor-intensive winterization process is now streamlined and efficient, thanks to the Airo system.

“Our collaboration with Vitalis underscores our unwavering commitment to innovation, ensuring we deliver top-tier extracts to the Canadian market at competitive prices.”

—Mark Aiken, CEO, Christina Lake Cannabis Corp.

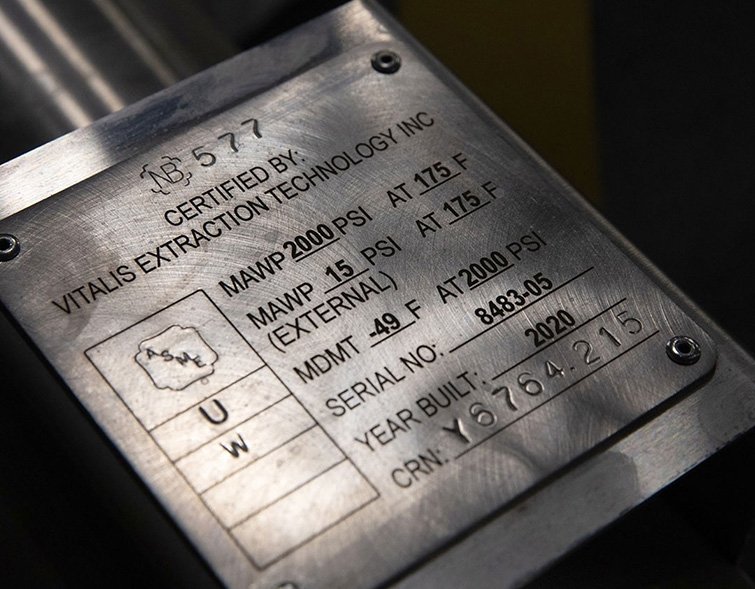

Certifications & System Compliance

Vitalis’ management system—for the design, manufacturing (welding and assembly), installation, and service of extraction technologies and commercial refrigeration—is certified as being in conformity with ISO 9001:2015 by Intertek.

Plan With Confidence

We’re in this for your long-term success. We don’t cut corners, and we don’t make wild claims.

Unbiased recommendations from experts with insider knowledge

End-to-end collaboration for making your product and revenue goals happen sooner

Quality assurance for the complex regulatory landscape—including the latest certifications and support for passing GMP inspections

Outmaneuver Your Competition

With Vitalis at your side, you’ll be a step ahead—compliant from the outset and ready to adapt when the inevitable happens (like stricter regulations or changing consumer preferences).

Compliance for today and tomorrow

Flexible solutions that let you push past traditional boundaries

Access to our in-house R&D team for when you want to test a novel use case

Maximize Throughput

Our solutions are reliable and engineered to last. We won’t leave you hanging. We’ll help you achieve smooth operations and maximum uptime so that you can reap maximum profits.

Global reach, with service technicians on 5 continents (and counting)

On-site training to get you started—and customizable options for additional training to keep you going

Dedicated service and support—available when you need it

What’s Possible for Your Business?

Here’s where we start finding out—together.