The third and final installment of this series reviews how processing parameters affect yields in extraction. Operating conditions, including extraction runtime and processing parameters, have a major influence on the yield obtained from an extraction.

There are many factors influencing yields in extraction. The first article in this three-part series presented a review of starting-material influence on extraction yields: the amount of starting material added to an extraction chamber, in addition to the content of compounds of interest intrinsic to that material, are important. Next, Part 2 examined the effects of material preparation: a finer particle size provides better packing efficiency, as well as greater efficiency of solvent-matrix interactions. Here, the final installment reviews the influence of operating conditions, elucidating how extraction runtime and processing parameters affect yields in extraction.

Effects of Extraction Runtime

An extraction operation should maximize yield while minimizing runtime and operating costs required to achieve the desired result. Consider Figure 1: as an extraction is initiated, the amount of material of interest obtained versus time sharply increases to Point Q, the maximum amount of material of interest extracted per unit time. After this point, the return of material obtained versus time gradually decreases until there is no material remaining (the extraction reaches completion).

Figure 1: Plot of the extraction of a component of interest with time. The axes represent the amount of material extracted versus time. The points marked on the plot are: P, the operating break-even point; Q, the point of maximum extraction efficiency; undefined R, the ideal point to halt the extraction with respect to maximizing profit; S, the operating profit line. Between the operating break-even point (P) and the operating profit line (S) lies the profitability region.

Three additional points are noted on the graph in Figure 1. Point P, the operating break-even point, defines the moment at which the extraction has recovered enough material to cover the costs incurred to allow operation for that extraction. Point S marks the position of the operating profit line along the extraction curve. The region between Point P and Point S is the profitability region; within it, the return from the product being extracted will more-than pay for all associated costs of the extraction. To the right of Point S, the costs of operation outweigh the return from the material obtained. The undefined Point R is the ideal point to halt the extraction. The precise location of Point R changes depending on factors such as the potency of the feedstock material, whether there is a finite or infinite amount of feedstock material to be processed, and the operation costs unique to each business.

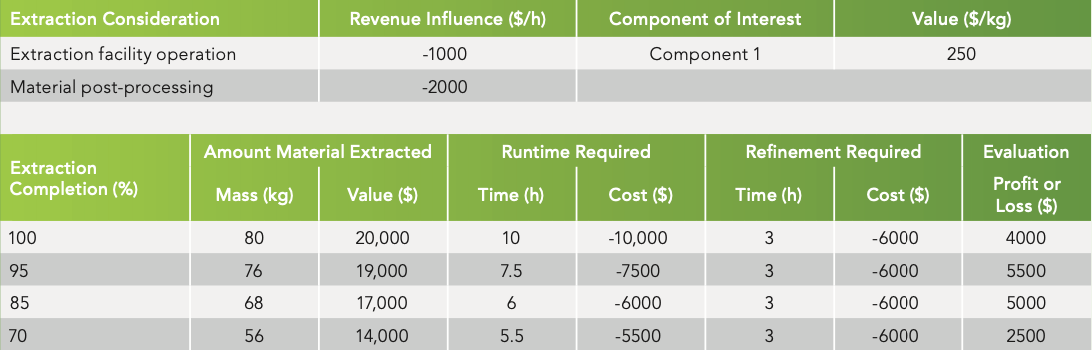

Consider the example scenario outlined in Table 1. Because of the way the general extraction curve is shaped, the runtime required to achieve a complete extraction may conflict with the cost of running the equipment or the facility. In this hypothetical production cost-revenue analysis, a day spent performing two extractions to 100% completion would bring $8,000 in revenue, whereas carrying out three extractions to 95% completion would turn a profit of $16,500.

Table 1: Example of a hypothetical production cost-revenue analysis

To ensure a business is profitable, an operation will want to exceed merely breaking even. There is no magic number for the time an extraction should be allowed to proceed. Rather, runtimes and return of material should be evaluated against facility operating costs as well as those incurred in refinement (post-processing) of the extract. A longer runtime may also provide access to one or more additional components of value or, conversely, may be associated with a higher concentration of undesirable material. It is up to each organization individually to establish the extraction conditions that, for them, make the return of operation worth the effort.

Processing Parameters

Along with runtime, processing parameters have a significant effect on extraction yields. In performing an extraction, an operator must choose the parameters that result in the highest yield of desirable components and the lowest yield of undesirable components. Furthermore, coextraction of desirable and undesirable components should be minimized to reduce downstream processing. In general, parameters that may affect extraction yield include temperature, pressure, and the solvent-to-feedstock ratio.

Figure 2: Plots showing extraction profiles for three components—1, 2, and 3—eluted in an extraction at a low-temperature (Plot A), medium-temperature (Plot B), and high-temperature (Plot C) extraction.

Consider Figure 2, which plots hypothetical extraction profiles of three components (components 1, 2, and 3) over three different extraction temperatures (low, medium, and high). The low-temperature run (Plot A) returned large amounts of components 1 and 2, which are coextracted; a small amount of component 3 is extracted with separation from other components. The medium-temperature run (Plot B) extracted large amounts of components 1 and 2 and a moderate amount of component 3, all with little to no coextraction. The high-temperature run (Plot C) saw all of components 1, 2, and 3 extracted in large amount; components 2 and 3 were coextracted.

If the operator is only interested in components 1 and 2 but not 3, they should select a low or medium temperature and halt the extraction before component 3 is extracted. If the operator is interested in components 2 and 3 but not 1, they should choose a high-temperature extraction. If the operator is interested solely in component 1, they should select a medium or high-temperature extraction and halt the run before component 2 is extracted.

Conclusion

Divided into three articles, this series has presented in-depth discussions of the factors influencing yields in extraction. To refresh and summarize the full breadth of concepts discussed, it is useful to consider a recipe providing the greatest yield of valuable components.

Beginning with the feedstock, a strain rich in desirable material with a minimum amount of undesirable material is chosen. This is the highest possible yielding option for starting material: the content of components of interest is maximized. Next, reducing particle size ensures that a maximum amount of material can be fit into the extraction chamber and increases efficiency of interaction of the solvent and feedstock matrix: a finer particle size increases packing efficiency and efficiency of solvent-matrix interaction. Extraction parameters will be selected that provide the most material extracted as well as the best separation from the undesirable components: a maximum amount of the component of interest is obtained and its elution is well-separated from unwanted components. Finally, the extraction will be run to completion such that every last bit of valuable material is extracted into the yield: the operation profit line is not a concern, all available material of value will be extracted.